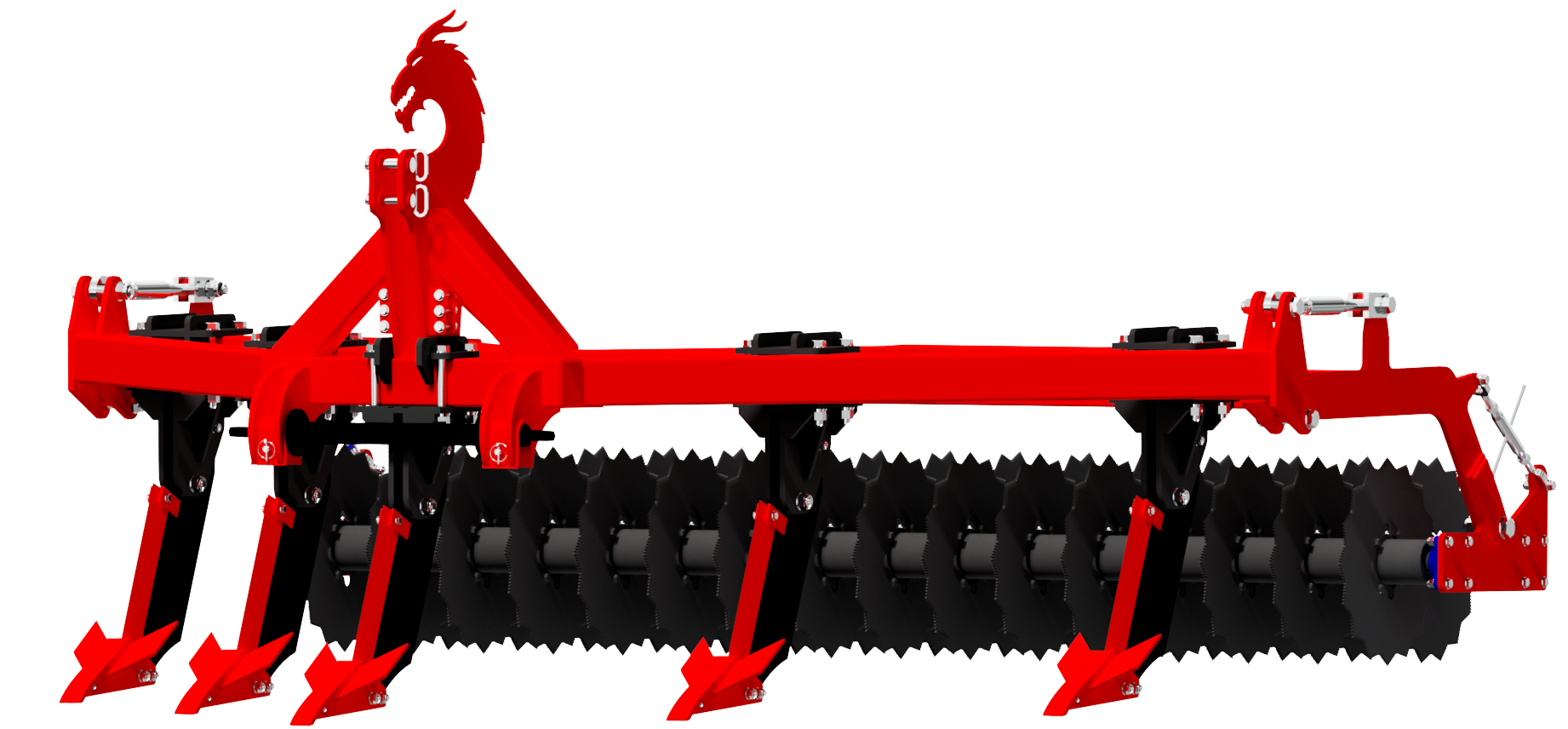

Row Cleaners for Planters: No-Till, Mini-Till, and Strip-Till Technology from the Manufacturer

Prepare the ideal seedbed and achieve uniform emergence regardless of the amount of crop residue.

In modern farming, where No-Till, Mini-Till, and Strip-Till technologies are becoming the standard for moisture conservation, farmers face a major challenge: how to plant effectively when the field is covered in straw? The answer is simple — professional row cleaners from LLC "Agropride".

We don't just sell iron. We offer a solution that has been working on Ukrainian fields since 2010.

Why does your planter need row cleaners?

Even the most expensive planter (John Deere, Kinze, Great Plains, or Horsch) won't reach its 100% potential if the opener disc pushes straw into the row. This phenomenon is called "hairpinning", and it is the main enemy of your harvest.

A row cleaner solves three critical tasks:

- Mechanical Residue Removal: Clears a 2-4 cm wide strip directly in front of the opener.

- Soil Warming: The dark soil in the row zone warms up faster, resulting in uniform emergence 2–4 days earlier.

- Disease Reduction: By moving moist residue away from the seed, you reduce the risk of rot and fungal diseases during the early vegetative stages.

Important: A properly adjusted cleaner does not dig a trench! It merely "sweeps" the surface, leaving the soil structure intact.

Why do experienced agronomists choose LLC "Agropride"?

The market is full of offers — from garage cooperatives to expensive imports. Why do leading farms in Ukraine work with us? Because Agropride is a manufacturer with an engineering approach, not just a reseller.

1. Experience since 2010

We started manufacturing row cleaners and turbo blades (coulters) when many were just learning the word "No-Till". We understand the geometry of the node assemblies of almost all existing planters.

2. Expertise in Materials

We do not save on steel. The working components of our cleaners are made from wear-resistant steel grades that undergo proper heat treatment. This guarantees that the discs won't lose their edge after the first 100 hectares, and the bearing units will withstand the loads of heavy soils.

3. Individual Approach and Compatibility Guarantee

Do you have a modernized planter? Non-standard mounting? Most sellers would shrug their shoulders. We will get it done.

- We analyze your planter model.

- We consider your working conditions (amount of residue, soil type).

- We offer the optimal design (rigid mount or floating cleaners).

4. Unique Service: Part "Test Drive"

We understand your concerns: "What if it doesn't fit?" That is why we introduced an ironclad rule:

First — a sample, then — the batch. When ordering, we manufacture 1 (one) control sample of the row cleaner. You receive it, mount it on the section, and check the geometry and operation. Only after your confirmation — "Everything is OK, fits perfectly" — do we launch the production of the full set for the entire planter. No risks for you.

Design Features of Agropride Cleaners

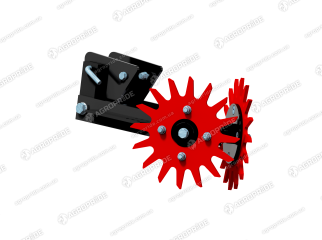

We manufacture various modifications to meet the needs of any farm:

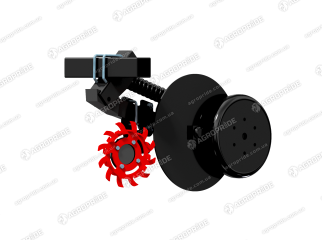

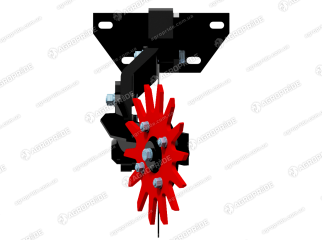

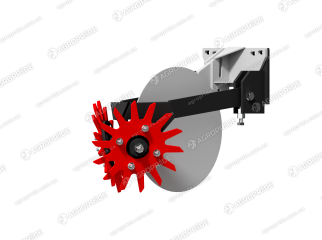

- "Shark Tooth" Type Discs: Aggressive discs for working with large amounts of residue (corn, sunflower). They easily cut and spread even wet mass.

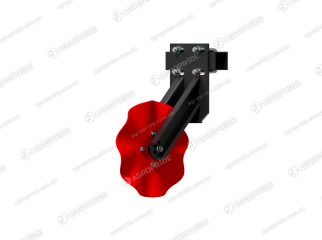

- Finger Cleaners: For more delicate work and less disturbance of the soil layer.

- Combinations with Turbo Blades (Coulters): For Verti-Till technology and heavy soils where additional loosening of the seeding zone is required.

Ready to increase planting efficiency?

Don't let crop residue steal your harvest. Order row cleaners directly from the manufacturer.

LLC "Agropride" — your confidence in every row.

Call us for a consultation. Our engineers will help select the ideal option specifically for your planter. Remember: we start with a test sample!

Frequently Asked Questions about Row Cleaners (FAQ)

Here we have gathered answers to the questions we hear most often from engineers and agronomists when ordering equipment from LLC "Agropride".

1. For which planter models do you manufacture row cleaners?

We have the drawings and manufacturing experience for assemblies for the most popular planters in Ukraine: John Deere (7000, 7200, DB series), Kinze, Great Plains, Horsch, Monosem, Vaderstad, and Challenger. Since we are a manufacturer, we also develop mounts for older models or planters that have undergone modernization. Everything starts with measurements and an individual drawing.

2. Which is better: rigid mount or "floating" mode?

It depends on the terrain of your field.

- Rigid Mount: Simpler, cheaper, and more reliable on perfectly flat fields.

- Floating Mode: Allows the cleaner to follow ground contours independently of the planter row unit. This is critically important on uneven fields to avoid "skips" in cleaning in hollows or excessive digging on hills. Our designs often provide for the possibility of adjusting both modes or using Depth Bands.

3. How to properly adjust the row cleaner in the field?

The main rule: the cleaner must rotate from contact with the residue, not the soil. It should not plow the earth or create a trench. Its task is only to sweep away the straw. If you see grooves or furrows from the cleaner discs after the planter pass — decrease the pressure or raise the unit higher. Proper adjustment preserves moisture and the lifespan of the discs.

4. What steel are the discs made of? Will they withstand No-Till?

We use high-quality alloy steel with mandatory heat treatment. We have been working since 2010 and know how heavy soil "eats" metal. Our discs (turbo blades and spike wheels) have a service life comparable to original spare parts from American brands, but at a much more pleasant price.

5. Can row cleaners be installed together with a coulter (turbo blade)?

Yes, this is a classic setup for Strip-Till or heavy No-Till. We manufacture combined units (Unit-Mounted Coulters / Combo), where the cutting disc (coulter) goes first, followed by the row cleaner. This allows for loosening the strip and removing plant residue at the same time. Our engineer will help configure this assembly so that it fits on the frame of your row unit.

6. How does your "test sample" service work?

We value your money and time. Therefore, the process is as follows:

- We agree on the design.

- We manufacture one cleaner and ship it to you.

- You install it on the planter, check if anything interferes, and ensure the mounts fit perfectly.

- Only after your confirmation, we manufacture the full batch for the entire planter. You risk nothing.